The only difference is that the head of a countersunk rivet is designed in a way that it will become concealed from the surface of the structure once it has been driven in place. Countersunk rivetĬountersunk rivets work very similarly to a standard rivet in that they both require access from both sides of the structure. This serves to fasten the rivet in place and to reduce the clearance between the rivet and the hole to as small as possible. Upon being driven using pneumatics or hydraulics, the tail of a standard rivet is deformed by a hammer or rivet gun. Standard rivers are considered some of the most reliable fasteners and are primarily used because they rarely fail.ĭue to the design of a standard rivet, it requires access to both sides of the materials being fastened. It is characterized by a round-head fastener, making it suitable for applications that don’t require a smooth finish on the surface of the material.

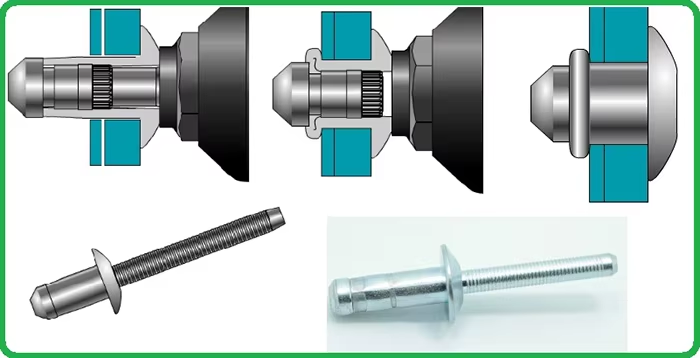

The standard rivet is the most common type of rivet and is probably familiar to many. There are close to a dozen different rivet types, but we’re focusing on three of the most commonly used: 1. For larger tension loads, bolts and screws are more recommended. However, it can also support tension loads at a limited capacity. The primary purpose of a rivet is to support shear loads oriented perpendicular to the axis of the shank. The riveting process may not be as widely used nowadays as it was back then, but it remains a relevant part of modern manufacturing methods.Ī rivet is typically made of carbon steel, but lightweight alternatives like aluminum and copper are also used quite commonly. It was the go-to fastening method for heavy-duty construction jobs like bridges, skyscrapers, airplanes, and automobiles. The use of rivets goes back to the Titanic and the tanks used in the Second World War.

In traditional wooden boats, copper nails and clinch bolts were used using the same principle as rivets, even before “rivet” was a term. Rivets have been an important component of construction processes for hundreds of years. On the other end is the tail, which needs to be bucked to set the rivet in place. On one end is the forged head which provides a fastener to the two parts. Its main cylindrical body, called the shank, pierces through the two parts being fastened together. If a riveted connection needs to be undone, the rivet must be destroyed by removing one of either of the two rivet heads. Since the bond created by a rivet is practically permanent, it is often used as an alternative to adhesive-bonded or welded joints. It is typically used to join two metal plates together. What is a rivet?Ī rivet is a permanent mechanical fastener typically characterized by a cylindrical body with a head on one end. What are rivets and what makes them so special? How are rivets applied to engineering and industrial parts? Let’s take a deep dive into the world of rivets. While there are hundreds of ways to do this, there are certain techniques reserved for applications that have practically zero room for failure.

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.Īmong one of the most important aspects of modern manufacturing technology is the ability to put separate components together accurately and reliably.

0 kommentar(er)

0 kommentar(er)